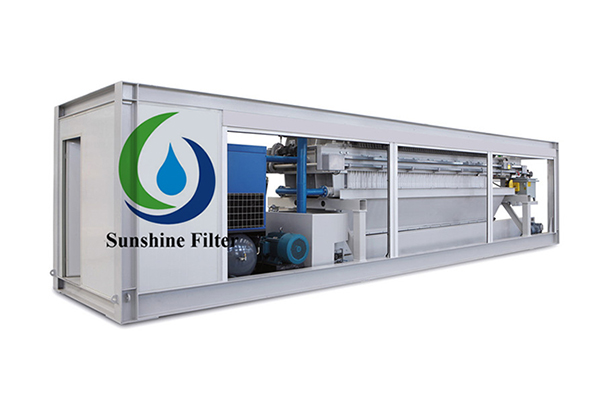

Features:

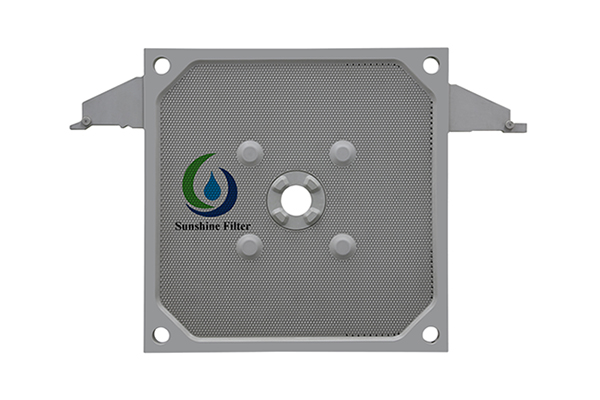

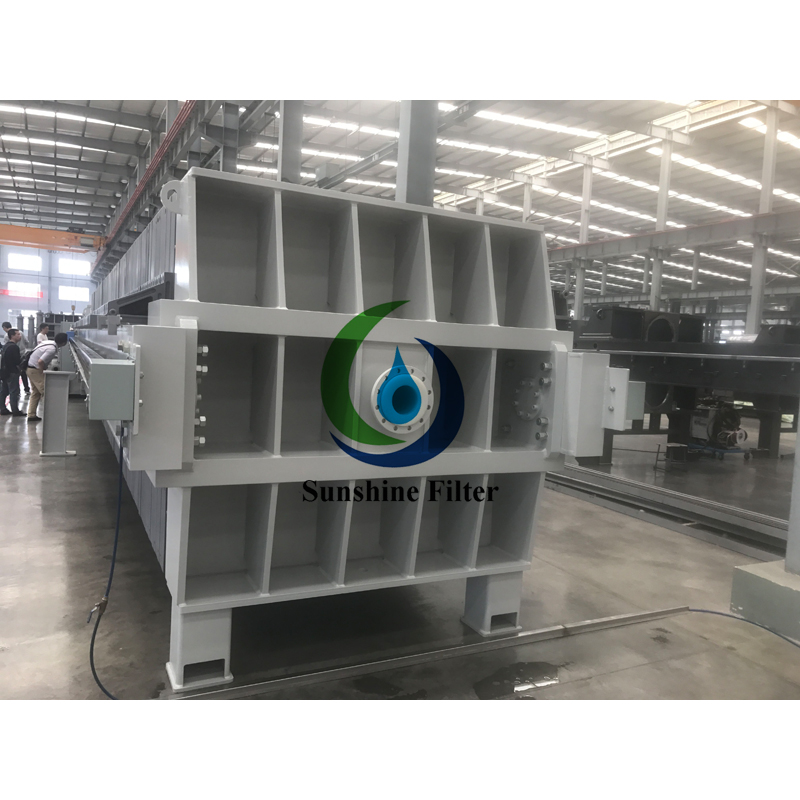

- Adopting the patent techniques, Moulding process the reinforced polypropylene into chamber plate featuring high intensity, light weight, anti-corrosion, acid and alkaline resistant, poison-less and smell-less;

- Auto. plate separate system. It is controlled by electric system or PLC control system;

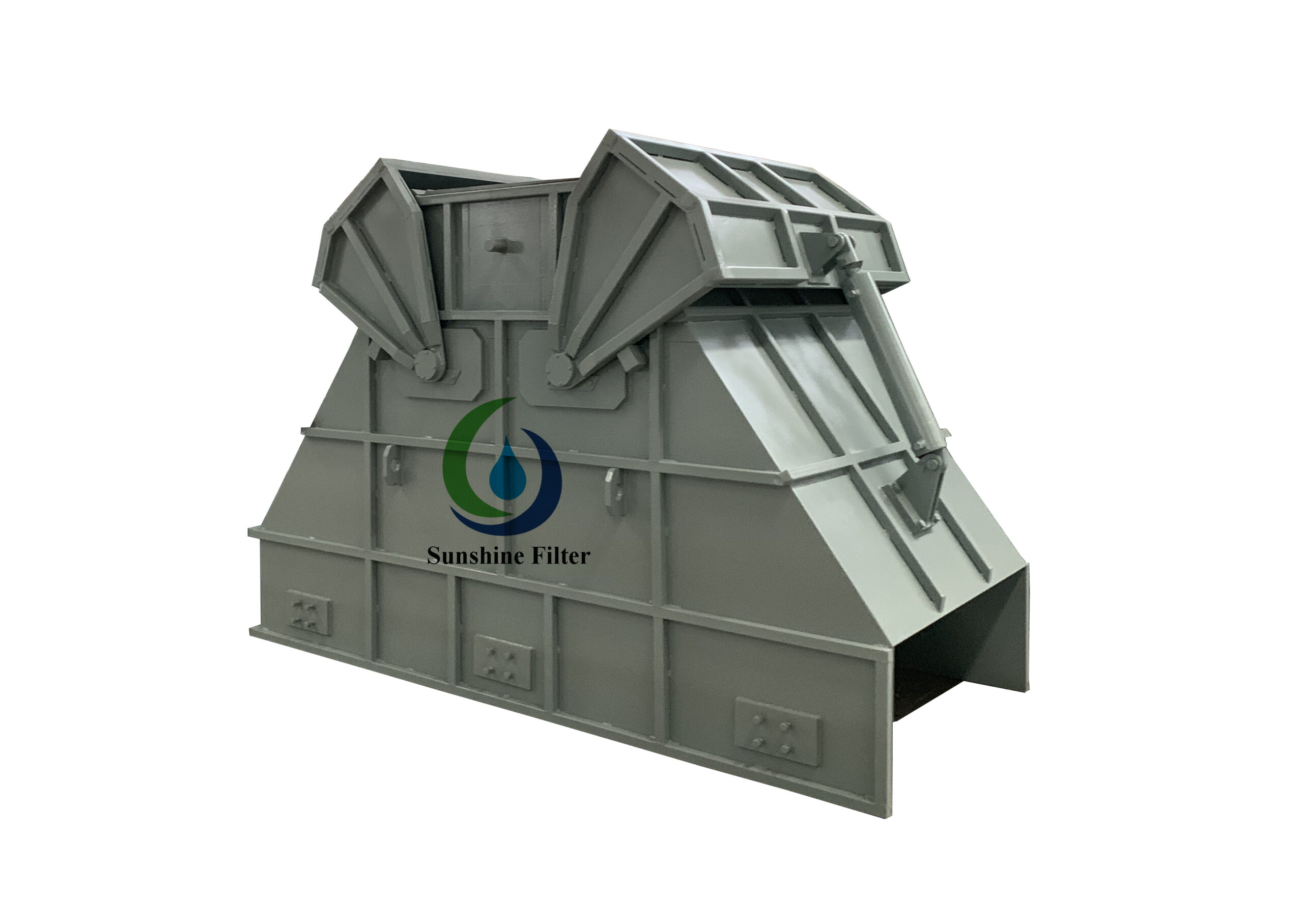

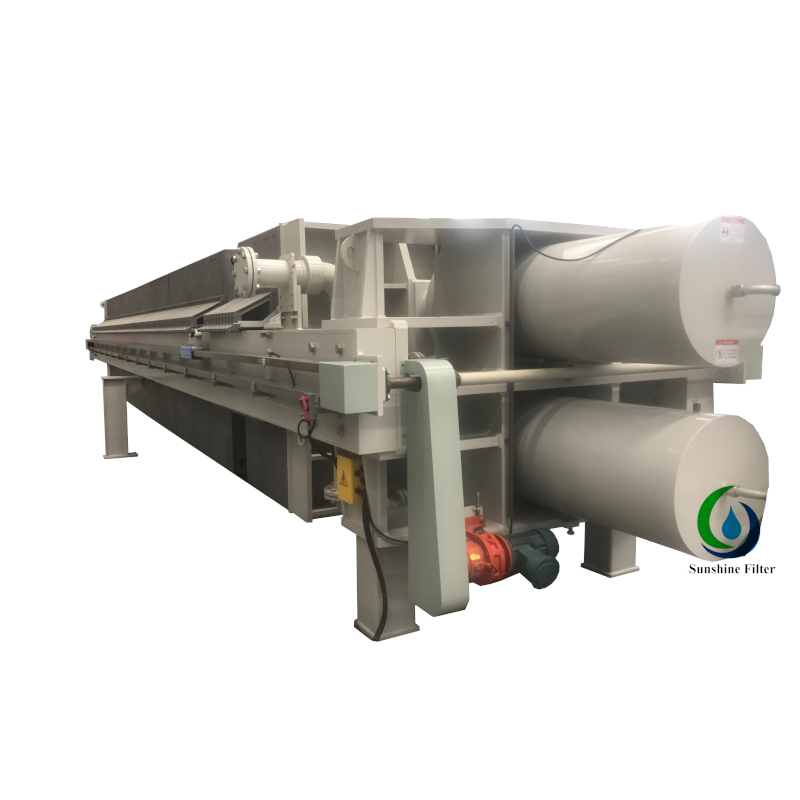

- The supporter is of welded steel structure with high strength for stress caused by cake weight and high pressure;

- Adopting auto. hydraulic system(auto. open and closed)with auto. maintaining pressure, and the max. pressure is 29Mpa to ensure the excellent sealing performance during filter;

- The side bars is connected to the thrust plate by hinge. It can freely moved to ensure sealing

- The double feeding inlets result in evenly-filtering and drier cake

- Press frame equip core blow system to decrease the moisture of cake

- Press the button on the electrical control board equipped with safe device to ensure safety to operators.

- Adopting double hydraulic cylinder with double oil pump to ensure its excellent pressure;

Application:

Solid-liquid separation of suspensions of all kinds, prevent fruitful in a wide spectrum of industries such as coal, petrochemical, metallurgy, pharmaceutical, light industry and textile, as well as environmental protection.

Filter area: 560-1190m2

Technical data

| Filter area(m2) | 560 | 630 | 700 | 800 | 840 | 910 | 1000 | 1190 |

| Capacity(L) | 9800 | 11030 | 12250 | 14000 | 14700 | 15930 | 17500 | 20830 |

| Machine Length(mm) | 10800 | 11600 | 12500 | 13800 | 14200 | 15010 | 16100 | 18200 |

Note :

1.The ” * ” the press frame equip middle support leg

2.the standard thickness of filter cake is 40mm, we can produce the different thickness according to the clients’ requirement.