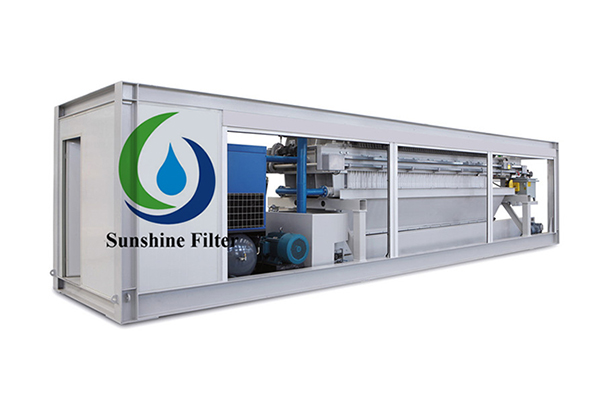

ADVANTAGES OF THE PLATE AND FRAME DESIGN

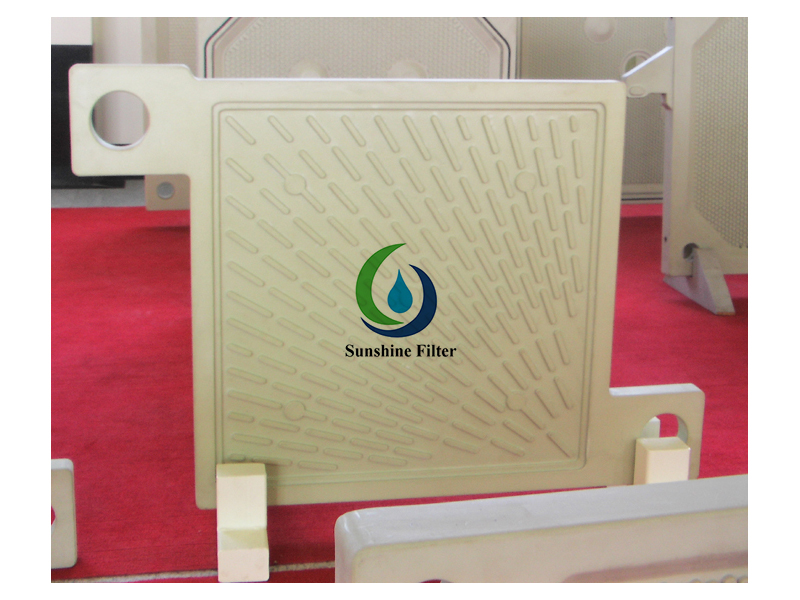

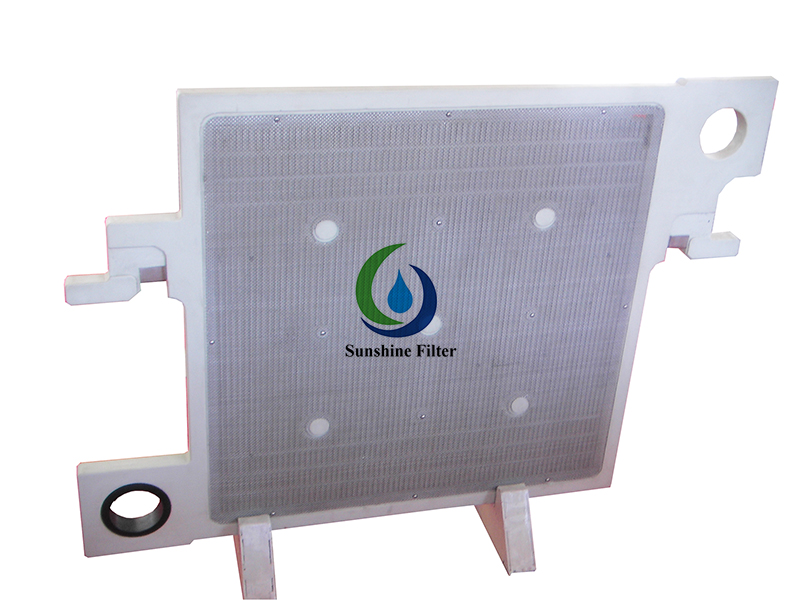

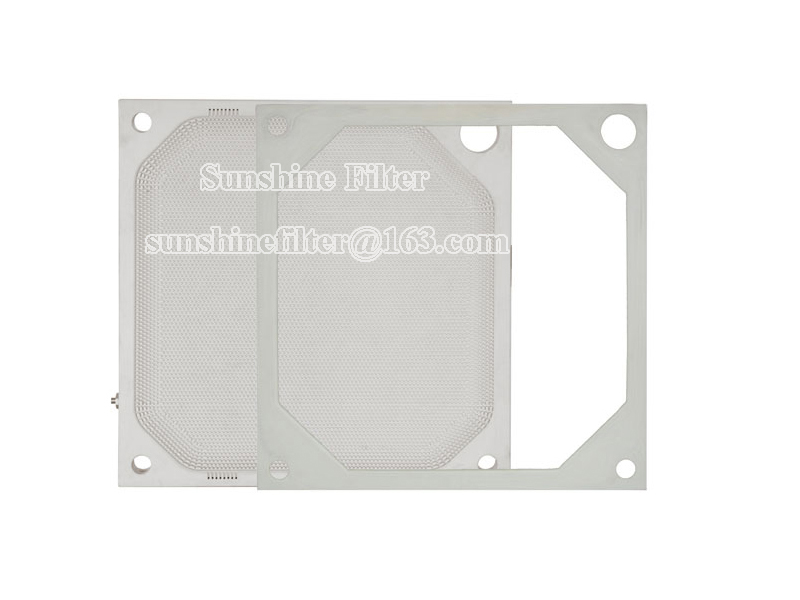

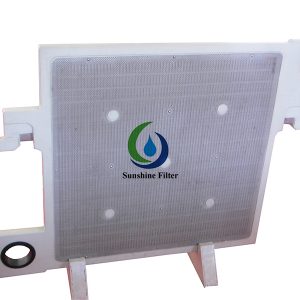

The primary advantages of plate and frame presses are the ability to quickly change the filter cloths as well as the ability to use a wider range of materials for the filtration medium, including paper, which is often used for fine filtration applications.

For example, in a process where immediate particle retention is important, filter paper may be required as fine solids would either blind off the filter cloth or simply pass through it. Note that filter cloths are still in place to support the filter paper. The filter cloths are reused, but the filter paper is replaced after every filtration cycle.

Plate and frame presses are best suited for projects where filtration area is more important than volume. This is why plates and frames have their greatest prominence in polishing applications (as opposed to dewatering projects), where the feed solids concentration is often well below 1% by weight.

Polishing applications are sized for a particular filtration area based on the process flow rate and the known flux rate (volume per area per unit of time). To avoid dips in achievable filtration flow as the press fills with solids, polishing applications usually include a redundant filter press that is also sized to accept 100% of the desired process flow.

DISADVANTAGES OF PLATE AND FRAME PRESSES

One disadvantage of the plate and frame design is the potential for building uneven pressure between frames, which can lead to plate damage. This issue stems from the fact that the frame is being fed through a small opening in the corner, which can lead to blockage. This clogging can cause one frame to become full while the next frame in-line remains empty.

Another disadvantage is the potential for leakage. The filter plates used in plate and frame presses are non-gasketed, which allows them to wick liquid under pressure. This type of filter press is usually mounted on a raised platform or positioned over a pit where any leaked liquids can be collected more conveniently.

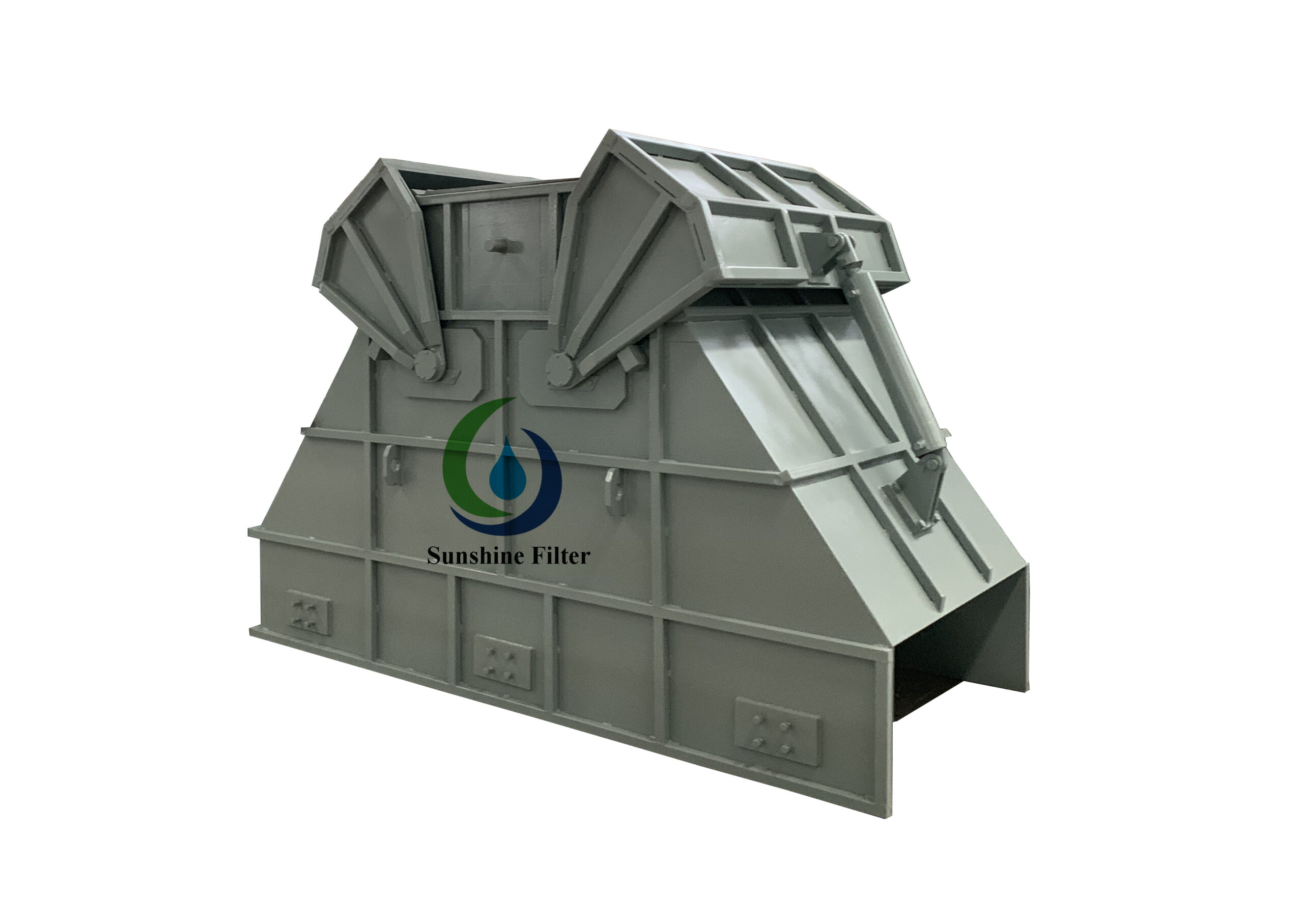

Application:

- Polishing

- Specialty chemicals

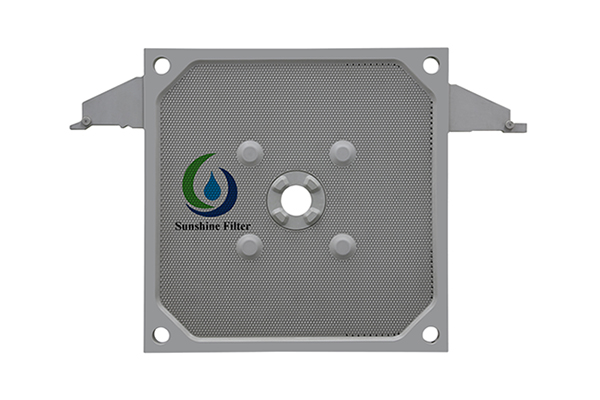

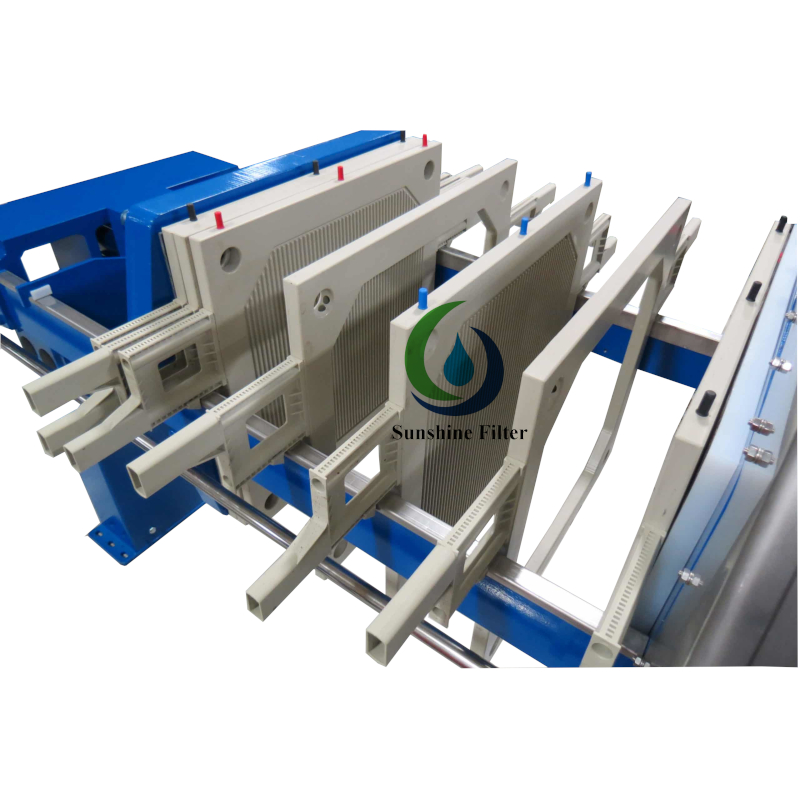

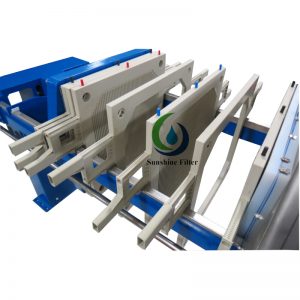

Plate&Frame size(mm): 800*800

Filter area: 10-60m2

Mainly Technical data

| Filter area(m2) | 20 | 30 | 40 | 50 | 60 | 70 |

| Capacity(L) | 320 | 480 | 640 | 800 | 960 | 1120 |

| Machine Length(mm) | 3585 | 4195 | 4805 | 5415 | 6025 | 6635 |

The kindly suggestion from Sunshine technology team that before we choose PP membrane filter press, we’d better to consider the following considerations

- Used for fine filtration where filter paper may be required

- Allows for different filter cake thicknesses by adding a thicker or thinner frame

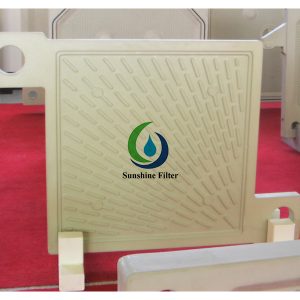

- Filter cloth drapes over plate

- You should expect some leakage

- Operated at lower pressures

- The standard thickness of filter cake is 25mm, we can produce the different thickness according to the clients’ requirement;