Filter Plate Gasket installation (and Removal) Instructions

The instructions below may seem confusing without video, if you have any trouble with the video, let us know.

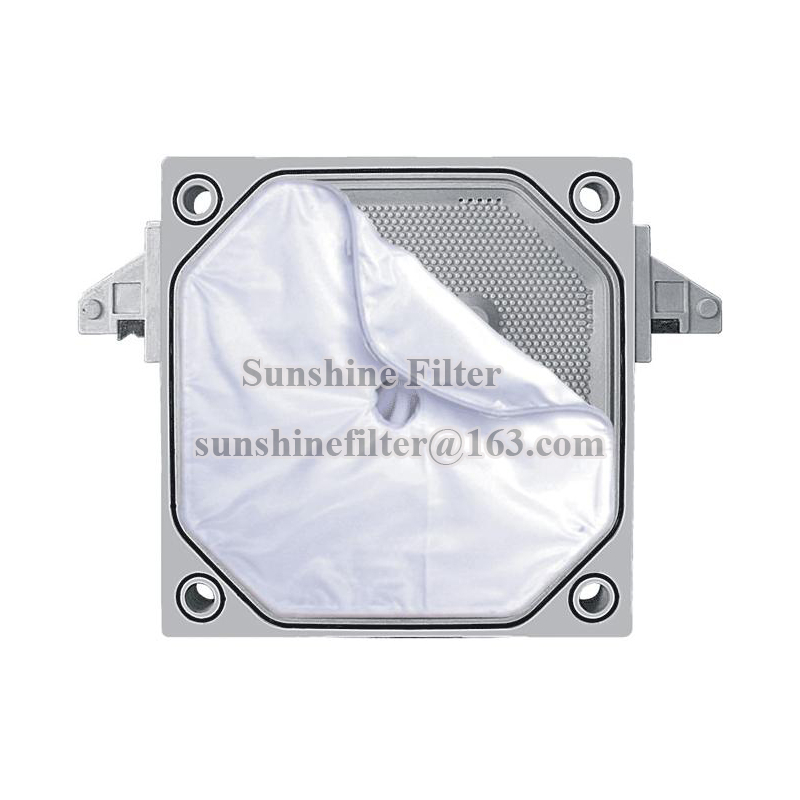

1) insert awl and pull up on gasket

2) Pull it out of the plate and discard

3) Check the groove for jagged edges;if found, use deburring tool to smooth

4) Squirt water and soap solution into groove; this lubrication eases installation

5) Insert gasket into the BOTTOM CENTER of plate

6) Begin pounding gasket into groove with deadblow hammer, leaving “humps every 2-3 inches

7) Continue pounding gasketing material into groove, leaving”humps” every2-3 inches, DO NOT STRETCH OR PULL GASKET MATERIAL

8) When you get all the way around filter plate, match ends of gasket and cut evenly with razor blade leaving about 1/8″ of overlap

9) Super glue one end of gasket and press ends together

10) Work your way around the plate, pounding the gasket humps into filter plate groove

11) Check for high spots you may have missed

12) Wipe excess solution off filter plate

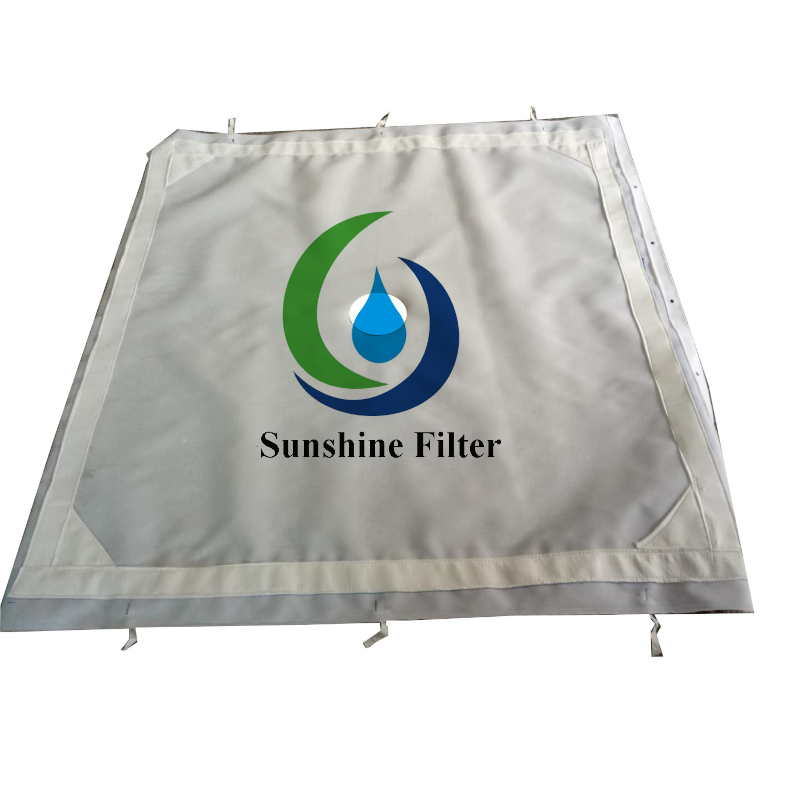

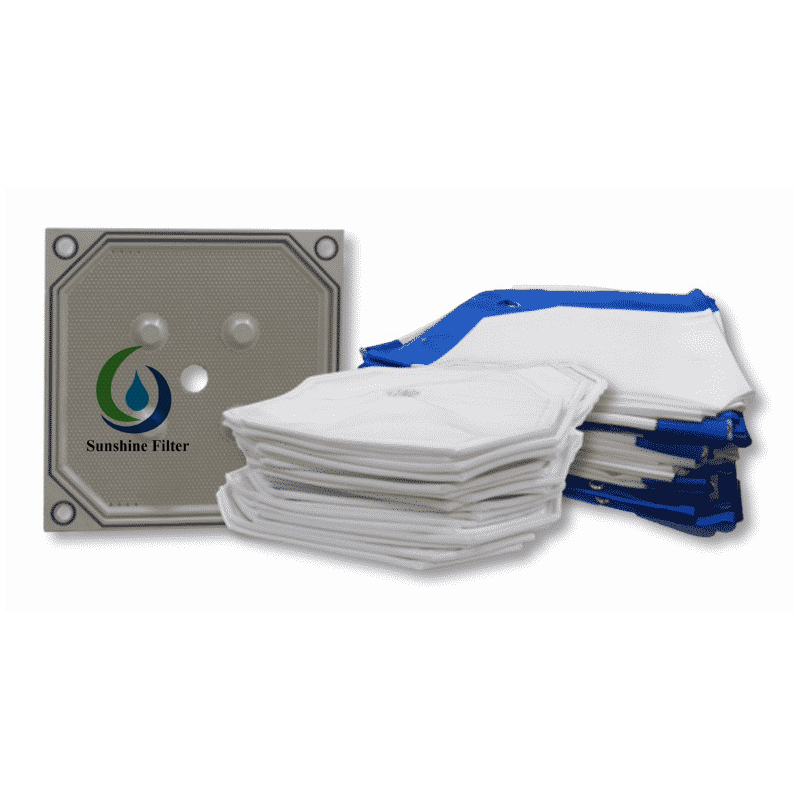

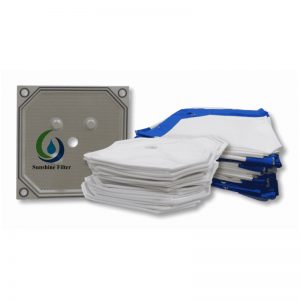

FILTER CLOTH SPECIFICATION

We place the emphasis on value, which is why we offer products that keep costs down. Our products are of the highest quality, and we offer filter cloths made of the following materials:

-Polypropylene, Polyester, Nylon, Vinylon, Felt

Mainly material properties are as followings:

|

Properties

|

Polyester

|

Nylon | Polypropylene | Vinylon |

| Acid-resistant | Very good | not good | good | bad |

| Alkali-resistant | not good | good | very good | very good |

| Conductibility | bad | better | good | common |

| Breaking Stretch | 30-40% | 18-45% | >30% | 12-25% |

| Recoverability | very good | >90% when

10% stretch |

good | not good |

| Wearability | very good | very good | good | better |

| Heat-resisting | 1700C | 1300C less contraction | 900C less contraction | 1000C contraction |

| Softening-point | 230-2400C | 1800C | 140-1500C | 2000C |

| Melting Point | 255-2650C | 210-2150C | 165-1700C | 2200C |

Note: The polyester cannot resist strong sulfuric acid and heated formic acid. The polypropylene cannot resist strong nitric acid, chlorosulfuric acid, strong caustic soda, strong acetic acid, and acrylic acid and chloro-aromatic hydrocarbon.

Besides for the better interception result and filter speed, choose filter cloth according to the granularity, density, viscosity, chemical composition and filtering technology conditions. Due to variety of filter cloth material and pattern, there are different strength, extension percentage, penetration and thickness of filter cloth, and thus the different filtering efficiency. In addition, the cotton cloth, adhesive-bonded fabric, mesh screen, filter paper and porous membrane also may be used for filtering medium. If you need any consultation service please contact with our technical team.