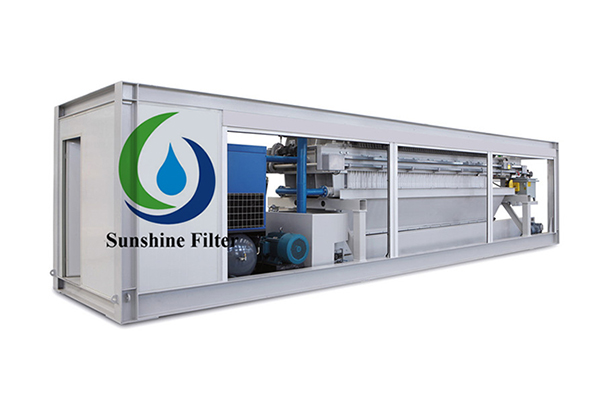

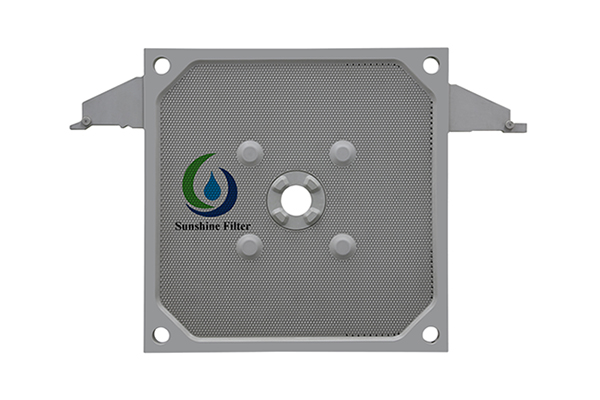

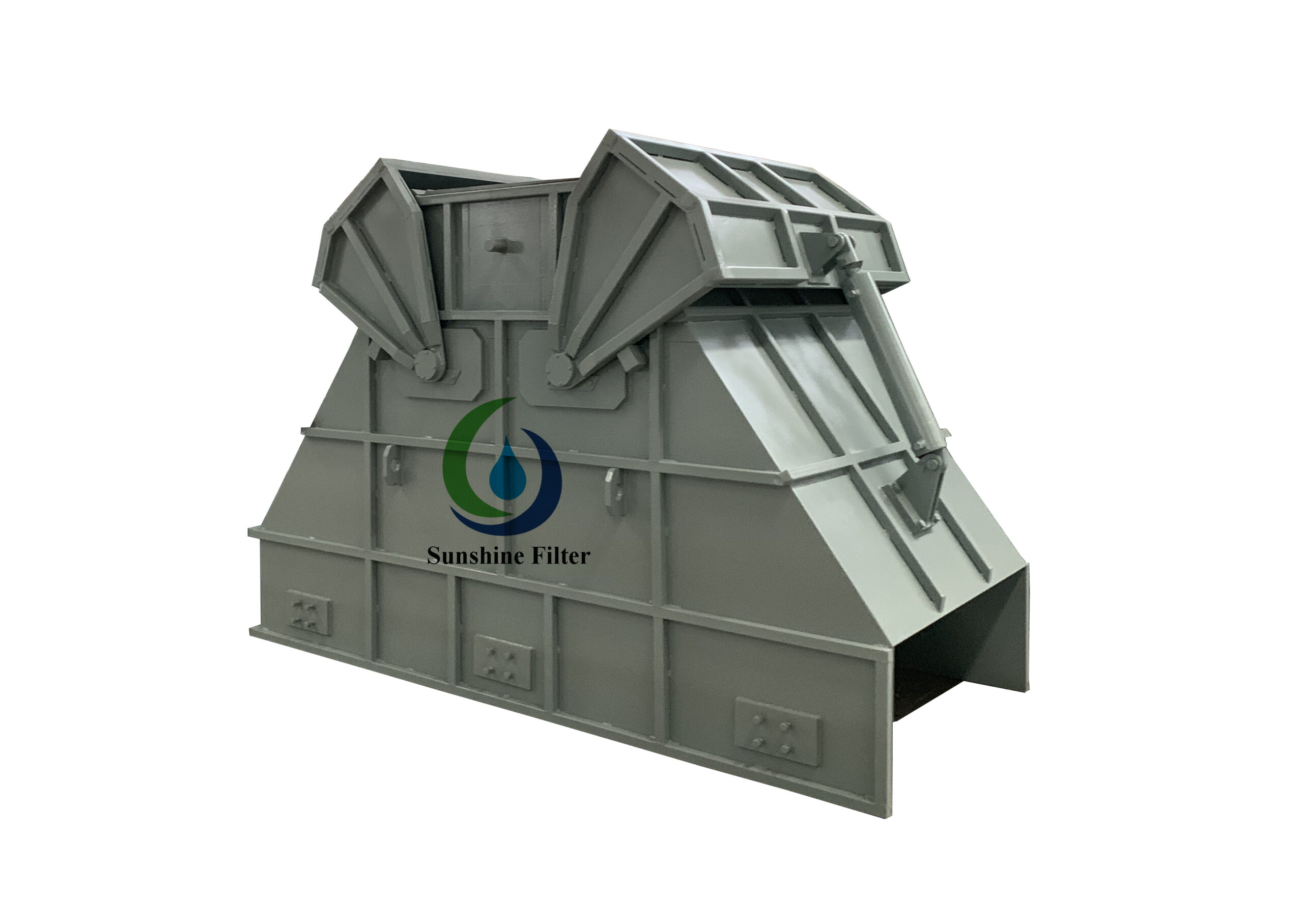

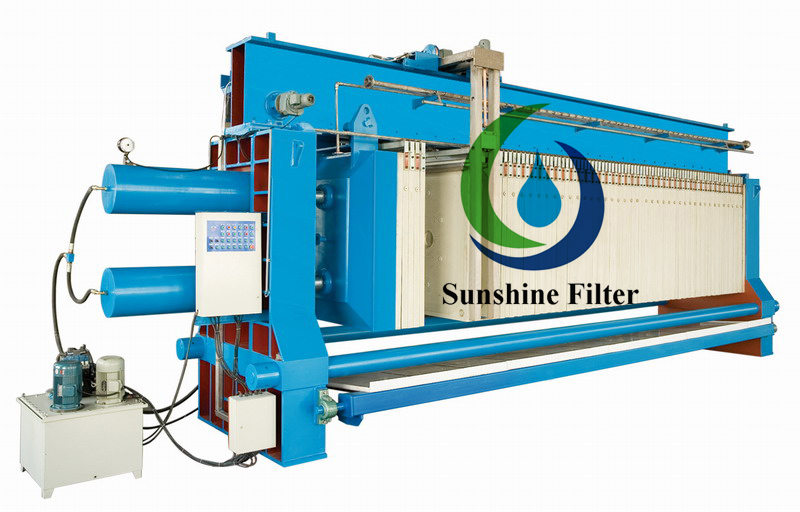

Overhead Beam Filter Presses are one style of recessed/membrane plate Filter Presses used to dewater and separate liquids and solids in a wide range of applications. Dewatering occurs when slurry material is pumped into the cavities created between the filter plates when they are hydraulically clamped together. The dewatered cake material accumulates between the filter plates, while the filtrate water passes through the filter cloths mounted on the plate surfaces.

The filter plates are mounted from an I-beam above the filter press, giving very good access to the filter plates and filter cloths. This orientation creates no interference when the dewatered filter cakes discharged and limits any slurry contamination with the plate opening carousel mounted in the I-beam.

Overhead Beam Filter Presses typically are used in applications when larger volumes of materials are being processed. The plate sizes and plate counts can be very large to accommodate the customer’s high processing rates.

Overhead Beam Filter Presses are used in a wide range of dewatering applications in many industries. Overhead Beam Filter Presses can hold larger plate sizes and a larger number of plates, making them more suited with high processing volumes. The overhead beam style press is well suited for dewatering material that are difficult to dewater slurries with high clay content, very fine particle size or organic materials. With the plate opening system mounted in the beam above the filter press, most of the moving components are well protected from contamination and wear associated with abrasive and corrosive materials. The overhead beam filter presses can be fully automated for continuous operations without full time operator monitoring.