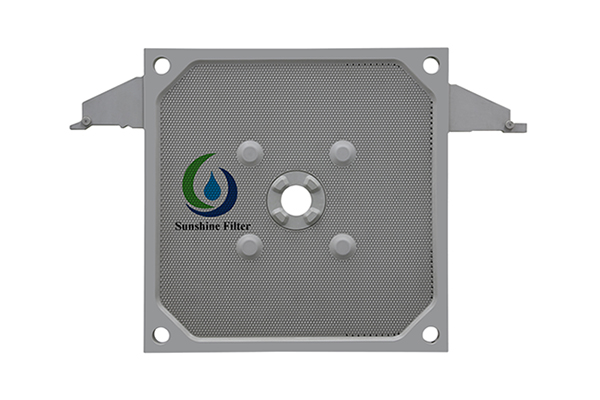

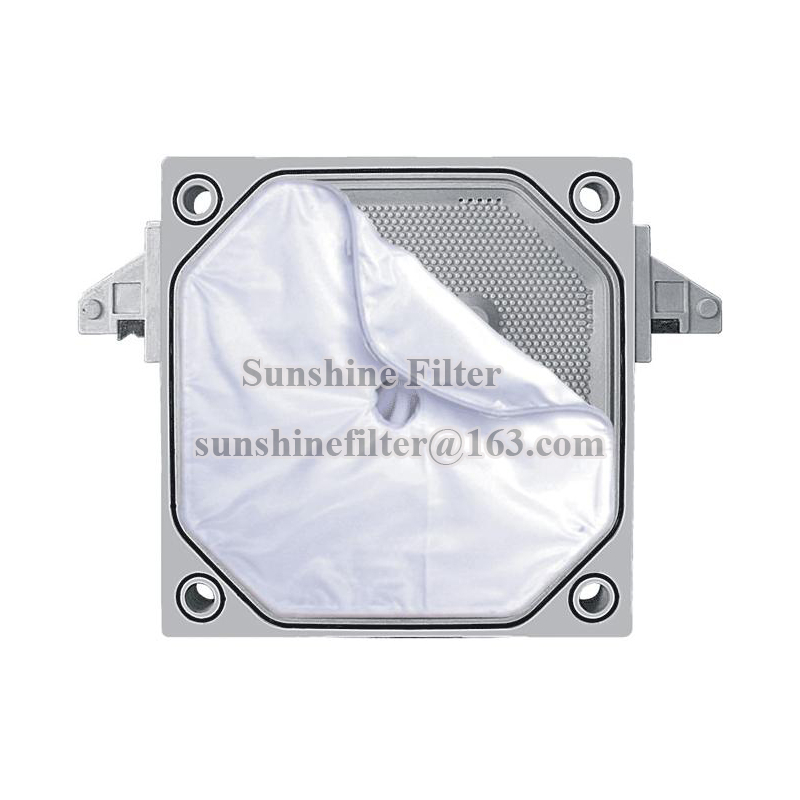

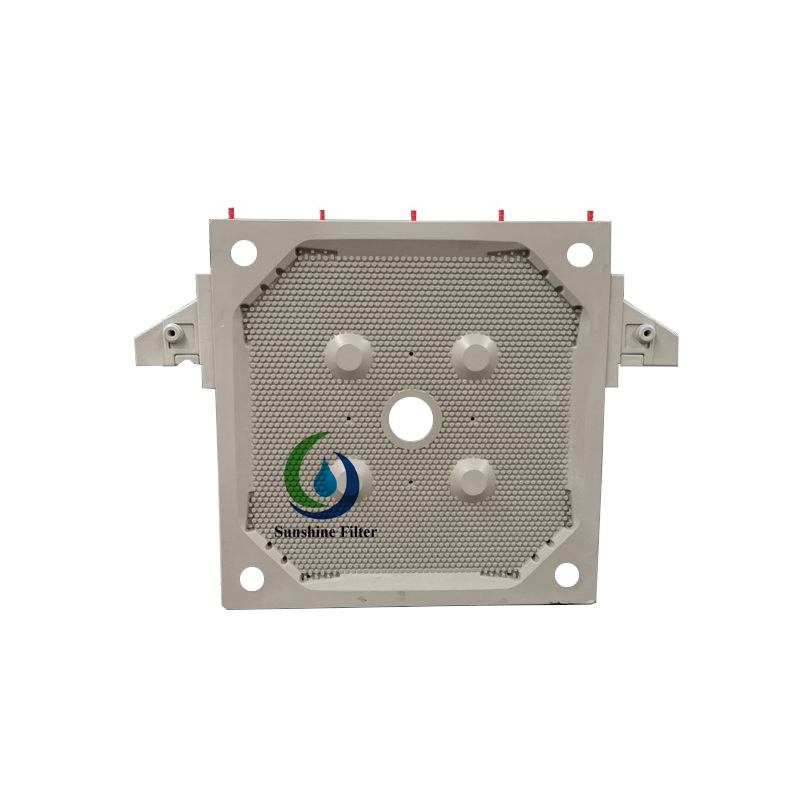

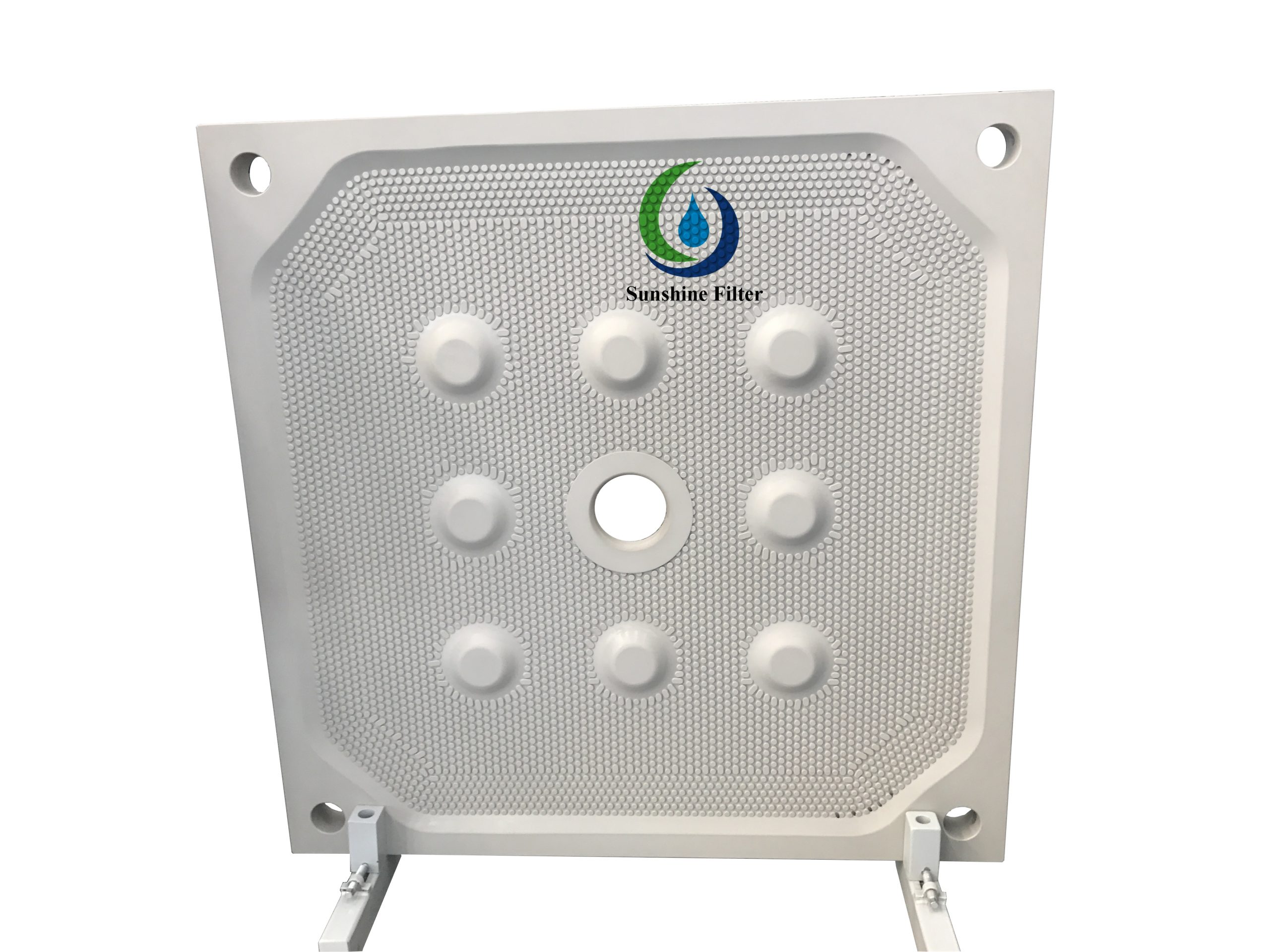

Characteristics

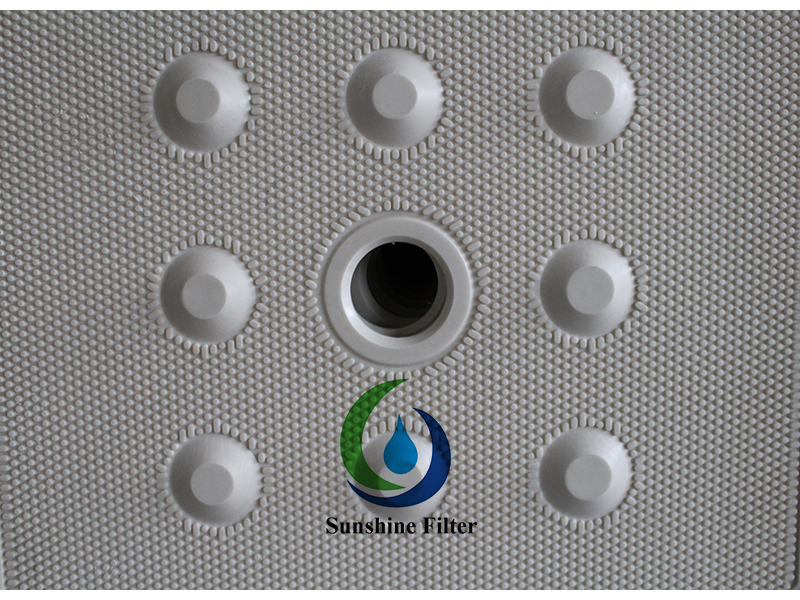

- Adopting the patent techniques, Moulding processthe reinforced polypropylene into chamber plate featuring high intensity, light weight, anticorrosion, acid and alkaline resisant, poisonless and smelless;

- High filter temp. & feeding pressure can be accept, the max.temperature can reach 140℃, and max.feeding pressure can reach 35bar

- Excellent anticorrosive and sealing performance

- Filtrate discharge fast and clean

- Lower moisture of cake

- Simple structure, lower failure, easy maintenance

SPECIFICATIONS OF PP RECESSED PLATE

| Model | Plate thickness, mm | Chamber, mm | Cake, mm | Filtration, m2 | Filtration volume, m3 | Weight, kg |

| 500×500 | 50 | 12.5 | 25 | 0.32 | 0.004 | 8 |

| 55 | 15 | 30 | 0.32 | 0.0048 | 9 | |

| 60 | 17.5 | 35 | 0.32 | 0.0056 | 10 | |

| 630×630 | 50 | 12.5 | 25 | 0.57 | 0.007 | 11.5 |

| 55 | 15 | 30 | 0.57 | 0.0085 | 13.5 | |

| 60 | 17.5 | 35 | 0.57 | 0.01 | 16 | |

| 800×800 | 55 | 15 | 30 | 0.95 | 0.014 | 23 |

| 65 | 17.5 | 35 | 1.54 | 0.017 | 26 | |

| 1000×1000 | 50 | 12.5 | 25 | 1.54 | 0.019 | 28 |

| 55 | 15 | 30 | 1.54 | 0.023 | 30 | |

| 65 | 17.5 | 35 | 2.3 | 0.027 | 32 | |

| 1200×1200 | 60 | 12.5 | 25 | 2.3 | 0.029 | 50 |

| 65 | 15 | 30 | 2.3 | 0.035 | 53 | |

| 70 | 17.5 | 35 | 2.4 | 0.04 | 56 | |

| 1250×1250 | 65 | 12.5 | 25 | 2.4 | 0.03 | 55 |

| 70 | 15 | 30 | 2.4 | 0.036 | 58 | |

| 70 | 17.5 | 35 | 2.4 | 0.042 | 60 | |

| 1500×1500 | 70 | 15 | 30 | 3.5 | 0.052 | 94 |

| 75 | 17.5 | 35 | 3.5 | 0.061 | 97 | |

| 80 | 20 | 40 | 3.5 | 0.07 | 100 | |

| 1600×1600 | 70 | 15 | 30 | 3.95 | 0.059 | 112 |

| 75 | 17.5 | 35 | 3.95 | 0.069 | 114 | |

| 80 | 20 | 40 | 3.95 | 0.079 | 116 | |

| 1500×2000 | 75 | 15 | 30 | 4.67 | 0.07 | 129 |

| 80 | 17.5 | 35 | 4.67 | 0.081 | 132 | |

| 75 | 20 | 40 | 4.67 | 0.093 | 136 | |

| 2000×2000 | 75 | 15 | 30 | 6.7 | 0.095 | 184 |

| 80 | 17.5 | 35 | 6.7 | 0.11 | 192 | |

| 85 | 20 | 40 | 6.7 | 0.13 | 196 |

We can produce the different and special size of the mould and plate according to the clients’ requirement if the order quantity is favourable;